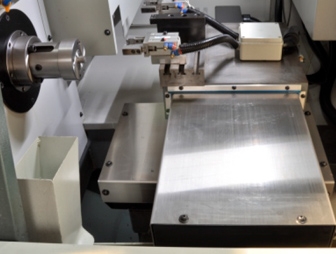

ORS-32 Flat Bed Lathe Machine

Designed for Precision Machining of Parts &Bar Stock Ultra-smooth operational motion High Parts Accuracy.

Applications

- Precision parts

- Precision nuts

- Watch parts

- Bar stock

- Hand tools

Feature

- Gang-type tooling system permits quick tool change.

- ER32 collet chucking

- Ø32 mm bar capacity

- 4,500 rpm spindle speed

- 30 M/min. rapid traverse on X, Y and Z-axes

- Additional exterior-mounted coolant tank

- Precision linear ways on X, Z-axes

- The base is manufactured from high quality Meehanite cast iron and stress relieved, featuring high rigidity without deformation.

- Syntec CNC controller

The first move does not move the board design

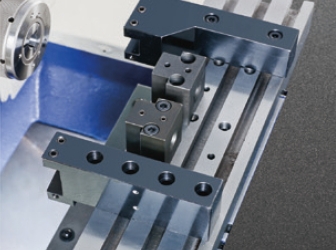

Gang-type Tool Rest

- They gang-type tool rest allows for the mounting of 4 tools.

- It accommodates 20x20 mm or 16x16 mm square tool shanks.

- It also accommodates Ø16 mm or Ø20 mm boring tool holders.

Gang-type Tool Rest

The spindle runs on high precision bearings for high speed rotation with minimum thermal growth, making the machine ideal for continuous operations.

Additional Exterior Mounted Coolant Tank

In addition to the original standard coolant tank, the OWNNER ORS-32 CNC lathe is specially designed with an additional exterior-mounted coolant tank. It allows coolant to be thoroughly chilled and filtrated.

Specifications

| Model | ORS-32S | ORS-32 |

|---|---|---|

| Max bar capacity | Ø25 / Ø30 / Ø32 | |

| Max turning length | Bar capacity x 3 | |

| Hole through spindle | Ø32 | |

| Collet-type | Germany makes 25E / 32E | |

| 3-jaw chuck size | 5 inch | |

| X-axis travel | 340 mm | 640 mm |

| Z-axis travel | 120 mm | |

| Spindle motor | 4.5 kw | |

| Max spindle speed | 6000 rpm | |

| Axis control motor | 0.75 kw | |

| Number of tools | 4 | 6 |

| O.D. tool shank sizes | 16x16 mm / 20x20 mm |

|

| I.D. tool collet | ER16 | |

| Boring tool shank | 20 mm | |

| Height of spindle center | 1080 | |

| Machine dimensions | 1600(W)x1560(H)x1300(D) | |

| Machine weight | 1250 kg | |

*Specifications subject to change without notice.

Standard Accessories

- Hydraulic collet chuck

- Gang type tool rest (16x16 mm / 20x20 mm)

- Leveling bolts and blocks

- Grease lubrication system

- Control (Syntec)

- Service tools x 1 Set

- Work lamp

- Pilot lamp

- Parts catcher

Optional Accessories

- 6" hydraulic chuck

- Hydraulic turret (6 positions)

- Chip conveyor (with cart)

- Bar feeder

- Oil mist collector

- Voltage stabilizer

- Control (Fanuc)

- Control (Mitsubishi M70P)

- Auto door

- External joi int foot switch

- Start and a stop the emergency switch